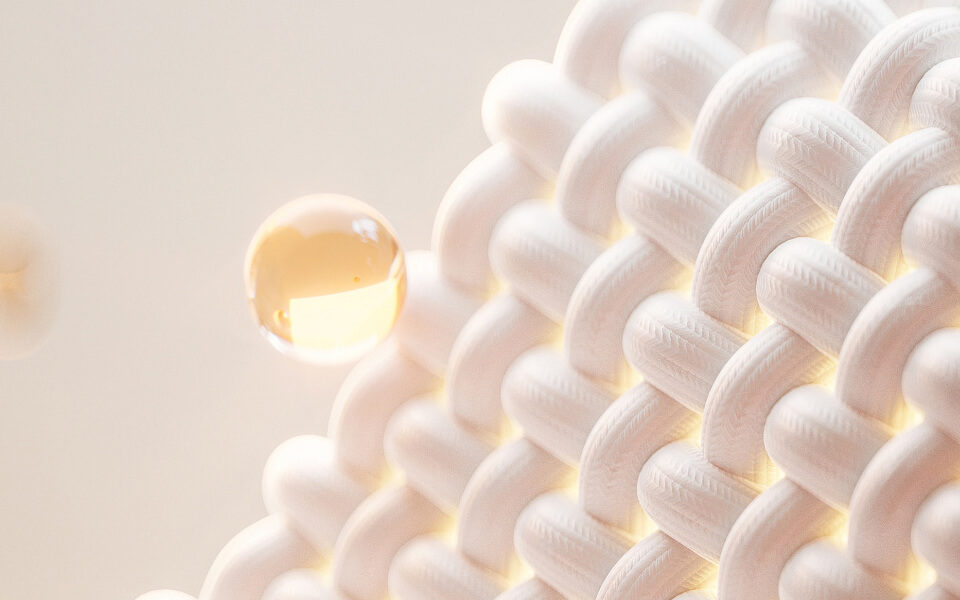

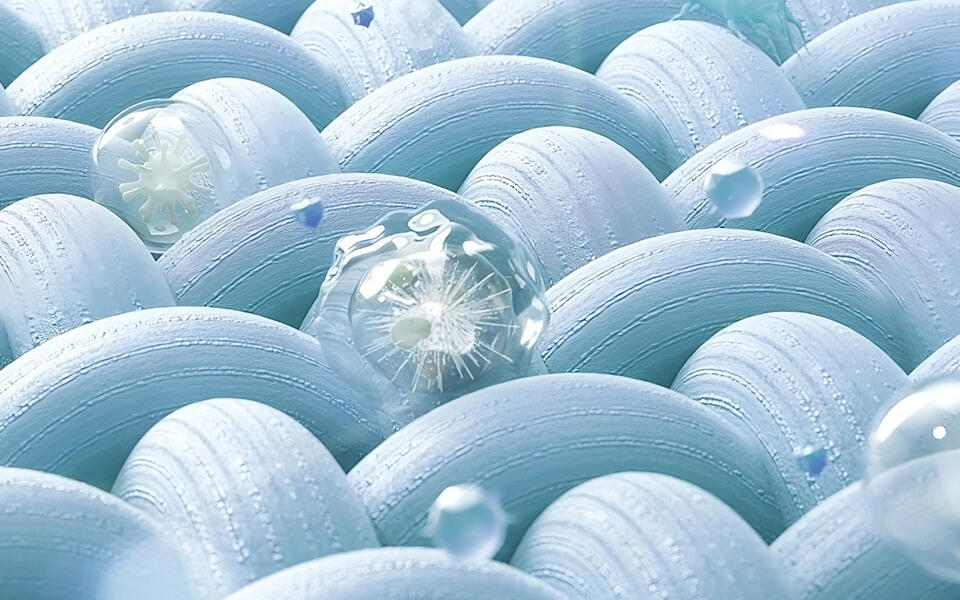

Physical cross-section modification is used to make the cross-section of the fiber appear in flat, triangular, dumbbell and other irregular shapes to achieve a certain mirror effect, reflect the light source, and achieve a flash effect.

-

Shiny gloss effect

-

Excellent fur texture

Explore More